Used in wave soldering production to avoid SMT patch parts and prevent hand-inserted components from rising.

Wave soldering fixtures are classified according to their uses and can be divided into three main categories:

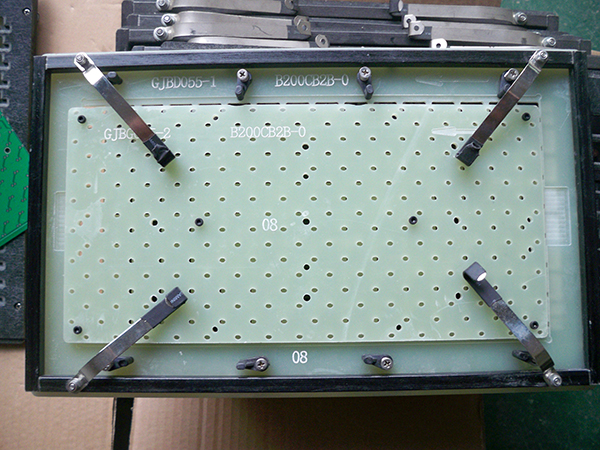

1. Welding-resistant trays are designed to improve the quality of the manufacturing process.

Used for wave soldering surface using solder paste reflow process to protect chip components during wave soldering and avoid secondary melting of solder joints;

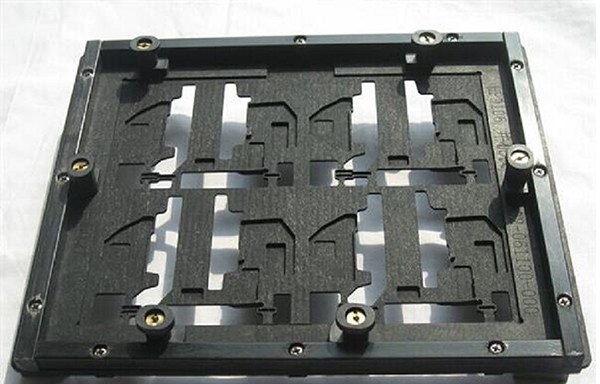

2. Plate pallets are used to improve production efficiency.

It is used for wave soldering of similar panels or different PCBs at the same time.

3. It is an auxiliary pallet for the purpose of other assembly process requirements.

It is used for auxiliary positioning of components on the board and irregular PCB over-board welding.